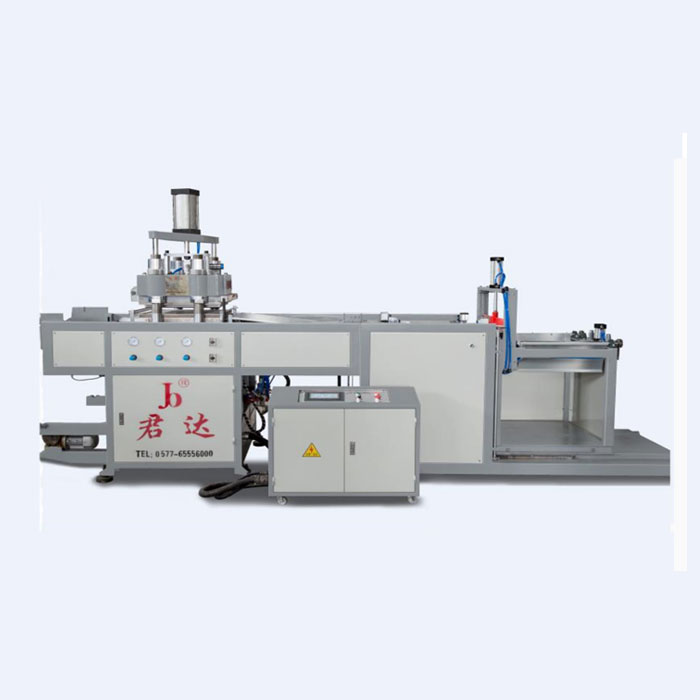

Category:Full automatic positive pressure thermoforming mac;Model:RJD-515X580LX-5

RJD-515×580LX-3 wired plastic pneumatic Thermoforming unit is an integrated design of machine, electricity, gas, and adopts PLC programmable control system, microcomputer control, and the same feeding manipulator stacking, human-machine interface operation. The product is completed by four stations of sheet feeding, heating, forming, trimming, and stacking. It is a plastic sheet forming equipment with simple operation, low power consumption, fast speed, and labor saving. It has manual, semi-automatic Three fully automatic operation functions. The general product cycle is between 2 and 6 seconds.

Mainly applicable to Bops, HIPS, PS,PP, PVC, PET plastic sheet heating molding, punching, stacking. Production of a variety of open-type boxes, plates, trays, bowls, lids and other oral liquid tray plastic packaging products. Such as food boxes, cake boxes, fast food boxes, pastry trays, supermarket trays, Medicine Injection Trays, oral liquid trays.

|

Models |

RJD-515×580LX-3 |

|

Maximum molding area |

515×580mm |

|

Maximum forming height |

100mm |

|

Sheet thickness range |

0.1-1mm |

|

Maximum roll diameter |

710mm |

|

Air flow |

2.5m3/min |

|

Heating plate power |

15Kw |

|

Formwork heater power |

4.8Kw |

|

Air pressure |

0..8Mpa |

|

Water consumption |

10(Liters/min)(10-20°C) |

|

Power source |

3-NAC380V±1.5V |

|

Production rate |

480-1500(Cycles/hr) |

|

Overall dimensions of equipment |

(L)9000*(W)1550*(H)2600 |

|

Equipment weight |

4300Kg |

|

Maximum atmospheric discharge |

2m3 |